In Spain there is the National Institute for Aerospace Technology (INTA), which is the government agency responsible for researchand development of aerospace technology officially within the national territory. Its functions are to conduct all necessary tests, technical advice, development of new technologies, offering services to other organisations and companies, etc.

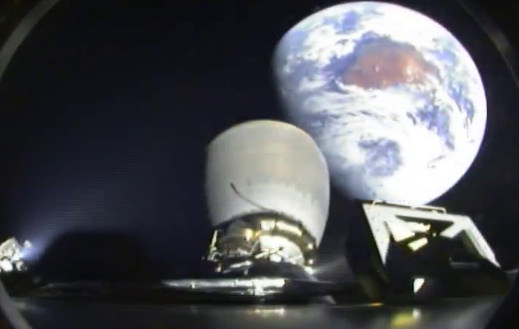

One of the projects that INTA stands out is that of stainless steel tubes . The tubes developed under its technology umbrella have served to manufacture the spacecraft engines, its destination the Moon.

The great advantage of these capillary tubes is its excellence to withstand the pressure level and its durability, enduring extreme and special conditions found on the Moon.

But it is not the only use of stainless steel capillary tubes . INTA has also participated in the creation of a machine that simulates the atmospheric conditions of Mars. Its vacuum chamber is composed of these tubes, that resist environments of 95% CO2 as of the Red Planet.

Our stainless steel capillary tubes are used in engine parts, either to transport various lubricants, such as to protect the electrical system to be conducted through the interior thereof.

Another common use of traded capillary tubes is to serve as a basis for pioneering projects or experimental aerospace engineering, such as those required by university students of this scientific branch.

Depending on the type of stainless steel tube chosen, a different welding is required, so that the joints can withstand the pressures andforces without affecting the final result. In fact, without the most advanced modern welding techniques, progress in aerospace would not be possible.

Capillary tubes are classified according to their diameter and wall thickness. That influences the internal pressure that can withstand and the pressure of the alloy used. In this case, are offered tubes of different ranges from 0.4 mm to 9 mm with different walls. For example, spacecraft X- 34 contained tubes between 6.35 mm and 114.3 mm with wall thicknesses ranging between 0.50 mm and 3.04 mm.

Similarly, capillary tubes are commercialised with different lengths, so they can adapt to all possible uses and with cutting tolerances of + – 0.2 mm.